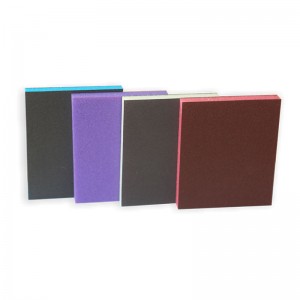

Aluminium oxide/Black silicon carbide/White front color

Art no.108.00

Velcro abrasive discs

MATERIAL: a. Aluminium oxide, C weight paper backing.

b. Aluminium oxide, E weight paper backing. Quality is 30% better than type a.

APPLICATION: With electric tools ideal for smoothing for raw wood, paint on wood and metal.

FEATURES: Powerful in grinding force, with high grinding efficiency. Strong adhesion strength, improved grinding efficiency.

GRITS:24-36-40-60-80-100-120-150-180-220-240-280-320-360-400-500-600.

DISCS: Dia.115mm, Dia.125mm, Dia.150mm, Dia.180mm, Dia.230mm.

DELTA SHEETS: 76mm, 80mm, 93mm, 105mm.

STRIPES: 93x230mm, 115x280mm, 80x230mm, 93x187mm.

Art no.109.00

Velcro abrasive discs(white front color)

MATERIAL: Aluminium oxide, semi-open coated, double resin binder, C-D paper backing.

APPLICATION: Specially recommended for auto-body work. Can be used on all unfinished and paint surfaces.

FEATURES: Coated to prevent clogging.

GRITS: 80-100-120-150-180-220-240-280-320-360-400-500-600.

DISCS: Dia.115mm, Dia.125mm, Dia.150mm, Dia.180mm.

DELTA SHEETS: 94mm, 105mm.

STRIPES: 93x230mm, 115x280mm.

Art no.109.10-C

Ceramic Disc

APPLICATION: Using special paper and abrasive grain, adopting advanced technology makes the product with the new appearance. This product has efficiency and long life, mainly used in automotive market, paint, putty, glass fiber and reinforced plastic. It also has the good extensibility.

GRIT RANGE: 60-80-100-120-150-180-220-240-320-400-600.

Art no.109.10-F

Film Disc

MATERIAL: The polyster film backing material creates a more flexible and much smoother abrasive surface, compared to paper backing. It can finish quickly and lasts long because of excellent resistance to clogging.

GRAIN: Aluminium oxide

BONDING: Resin over resin

BACKING: PET

COATING: Semi-open

GRIT RANGE: 40-2000

Art no.109.10-G

Gold Disc

TYPE: It could be produced with velcro as well as PSA.

GRAIN: Aluminium oxide and Zirconium oxide

BONDING: Resin over resin

BACKING: C latexed paper

COATING: Semi-open

GRIT RANGE: 40-1200

Art no.109.10-P

Pink Disc

TYPE: It could be produced with velcro as well as PSA.

GRAIN: Aluminium oxide and Zirconium oxide

BONDING: Resin over resin

BACKING: C latexed paper

COATING: Semi-open

GRIT RANGE: 60-1200

Art no.109.20

Silicon carbide Velcro abrasive discs

MATERIAL: Black silicon carbide abrasive, semi-coated, double resin binder.

APPLICATION: Good use for stone and fiberglass products.

FEATURES: High sharpness and keen for working surface. Good quality velcro material.

GRITS: 40-60-80-100-120-150-180-220-240-280-320-360-400-500-600-800-1000

DISCS: Dia. 115mm, Dia.125mm, Dia.150mm, Dia 180mm

DELTA SHEETS: 94mm, 105mm

STRIPES: 93x230mm, 115x280mm

Art no.109.30-NET III

ORIENT NET

MATERIAL: Aluminium oxide, semi-coated, resin over resin.

APPLICATION: Especially developed for sanding putty, primers, lacquers, composite materials and a large amount of other materials.

FEATURES: Orient Net is an innovative and totally unique dust-free, sanding system "net sanding". It is a standard multifunctional net product.

GRITS: 80-100-120-180-240-320-400-600-800

Velcro abrasive discs also known as brushed disc sandpaper velcro sandpaper

Common specifications of common products include round, rectangular, triangular sand and other shapes, and can also be made into vacuum holes.

The brushed sheets sold in the general market are from 2 inches, 3 inches, 4 inches, 5 inches, 6 inches, 7 inches, 8 inches. After classification of the sand surface of the brushed sheet: red sand surface, white sand surface, yellow sand surface, green sand surface, blue sand surface, black sand surface, etc.

The raw materials of sandpaper are divided into silicon carbide, alumina and zirconium corundum. Silicon carbide is divided into green silicon carbide and black silicon carbide. Alumina is divided into brown corundum and white corundum, and brown corundum is divided into ordinary brown corundum, calcined brown corundum, iridium-plated brown corundum, semi-brittle corundum, etc.

The biggest difference between the brushed sheet is that the back is planted with flannel, which is very simple to distinguish it from the adhesive disc sand. The brushed sheet is easier to exchange than the adhesive disc sand in use, and the grinding power is improved; it can be soaked in water for grinding, A greater level of improvement in wear resistance.

The raw materials of sandpaper are divided into silicon carbide, alumina and zirconium corundum. Silicon carbide is divided into green silicon carbide and black silicon carbide. Alumina is divided into brown corundum and white corundum, and brown corundum is divided into ordinary brown corundum, calcined brown corundum, iridium-plated brown corundum, semi-brittle corundum, etc.

The difference between the brushed sheet is that the flannel is planted on the back, which is very different from the adhesive disc sand. The brushed sheet is easier to exchange than the adhesive disc sand in use, and the grinding power is improved; it can be soaked in water for grinding, and the larger the Level of progress wear level.