Type 27 Fibreglass Reinforced Depressed Center Grinding Wheels

Choose the abrasive grain as follow

a) A—for general metal.

b) ZA or WA—for stainless steel.

c) C or GC—for non metal, stone etc.

Features

Sharp, with long service life and superior cost performance.

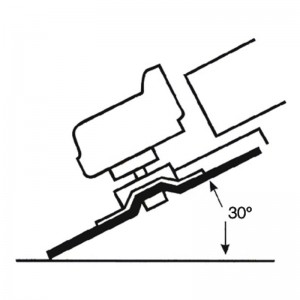

Key points for best results.

Hold your right angle grinder at 30°with notcher.

Run the gringer according to the highest possible speed marked on the wheel.

Higher power and speed of the grinder, higher efficiency.

| Size(mm) (DiaxDepthxHole) |

Max Speed Rounds/Minute |

Application | ||

| Metal | Stone | Stainless steel | ||

| ⭐100x3.0x16 | 15300 | Art no.202.000 | Art no.202.100 | Art no.202.200 |

| ⭐100x4.0x16 | 15300 | Art no.202.001 | Art no.202.101 | Art no.202.201 |

| ⭐100x6.0x16 | 13300 | Art no.202.003 | Art no.202.103 | Art no.202.203 |

| 100x7.0x16 | 13300 | Art no.202.004 | Art no.202.104 | Art no.202.204 |

| 115x3.0x22.23 | 13300 | Art no.202.006 | Art no.202.106 | Art no.202.206 |

| 115x4.0x22.23 | 13300 | Art no.202.007 | Art no.202.107 | Art no.202.207 |

| 115x6.0x22.23 | 13300 | Art no.202.009 | Art no.202.109 | Art no.202.209 |

| 115x7.0x22.23 | 13300 | Art no.202.010 | Art no.202.110 | Art no.202.210 |

| 125x3.0x22.23 | 12250 | Art no.202.012 | Art no.202.112 | Art no.202.212 |

| 125x4.0x22.23 | 12250 | Art no.202.013 | Art no.202.113 | Art no.202.213 |

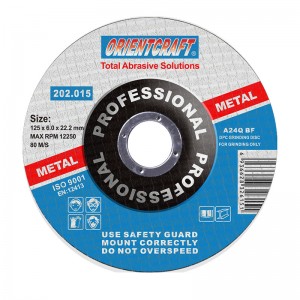

| ⭐125x6.0x22.23 | 12250 | Art no.202.015 | Art no.202.115 | Art no.202.215 |

| 125x7.0x22.23 | 10200 | Art no.202.016 | Art no.202.116 | Art no.202.216 |

| 150x3.0x22.23 | 10200 | Art no.202.018 | Art no.202.118 | Art no.202.218 |

| ⭐150x6.0x22.23 | 10200 | Art no.202.021 | Art no.202.121 | Art no.202.221 |

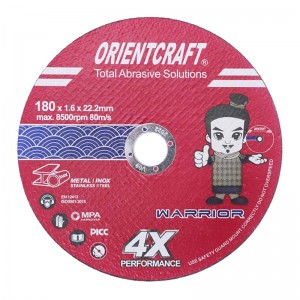

| 180x3.0x22.23 | 8500 | Art no.202.024 | Art no.202.124 | Art no.202.224 |

| ⭐180x6.0x22.23 | 8500 | Art no.202.027 | Art no.202.127 | Art no.202.227 |

| 180x7.0x22.23 | 8500 | Art no.202.028 | Art no.202.128 | Art no.202.228 |

| 180x8.0x22.23 | 8500 | Art no.202.029 | Art no.202.129 | Art no.202.229 |

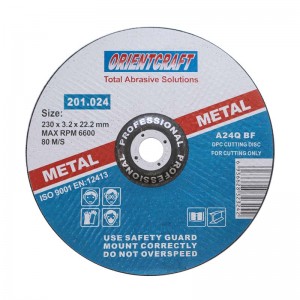

| 230x3.0x22.23 | 6650 | Art no.202.030 | Art no.202.130 | Art no.202.230 |

| 230x6.0x22.23 | 6650 | Art no.202.033 | Art no.202.133 | Art no.202.233 |

| 230x7.0x22.23 | 6650 | Art no.202.034 | Art no.202.134 | Art no.202.234 |

⭐Popular size in China market

Common problem and solution for cut-off wheel

Solution

● The cutting wheel consumption fast

Select and adopt the models with high hardness level

Decrease the grinding pressure

● The inner bores of cutting disc craze

Move forward and backward evenly, and exert pressure along the diametrical direction.

Use the grinding disc in grinding process.

Avoid to exert pressure in side direction.

Apply the flange plate with the same diameter in inner side and outer side.

● The edge crazes while the abrasion wheel is cutting

Replace the flange plate with large diameter and generally the diameter of flange plate should be required to reach 1/3 of that of the abrasion wheel.

Adjust the pressure of the flange and abrasion wheel to a reasonable level.

Decrease the load while cutting and reduce the pressure inside direction.

Replace the flange plate with large diameter and generally the diameter of flange plate should be required to reach 1/3 of that of the abrasion wheel.

● The fracture of workpieces is burnt severely

Adopt the abrasion wheel of low hardness level and high efficiency.

Replace it with high work rate.

Adjust the tightness of the belt.

Adopt the abrasion wheel of low hardness level and high efficiency.