Newly Arrival Diamond Sandpaper - Diamond series products – Orientcraft

Newly Arrival Diamond Sandpaper - Diamond series products – Orientcraft Detail:

Process classification

1. Sintered diamond saw blade: it is divided into cold press sintering and hot press sintering.

2. Welding diamond saw blade: it is divided into brazing and laser welding. Brazing is to weld the cutter head with the matrix through high-temperature molten medium, such as high-frequency induction brazing saw blade, vacuum brazing saw blade, etc; In laser welding, the contact edge between the cutter head and the substrate is melted by high-temperature laser beam to form metallurgical bonding.

3. Electroplated (brazed) diamond saw blade: the cutter head powder is attached to the substrate by electroplating. Since 2012, the state has gradually cancelled the production of electroplated diamond products, mainly because of the serious pollution.

Appearance classification

1. Continuous edge saw blade: continuous sawtooth diamond saw blade is generally made by sintering method. Bronze bond is commonly used as the basic matrix material. Water must be added during cutting to ensure the cutting effect, and laser is used to cut the gap.

2. Cutter head saw blade: the sawtooth is broken and the cutting speed is fast. It is suitable for dry and wet cutting methods.

3. Turbine saw blade: combined with the advantages of the first and second items, the sawtooth continuously presents turbine shape, uniform convex and concave, which improves the cutting speed and service life.

Scope of application

1. Processing of difficult to process nonferrous metal materials

2. Processing of difficult to process non-metallic materials

3. Ultra precision machining(4) Particleboard woodworking

Ceramic hot pressed blade

| Art no. | Outer Diameter | Inner Diameter(H) | Segment Dimension | ||

| Inch Metric(mm) | Inch Metric(H) | ||||

| 1003.01 | 4” | 105 | 5/8″ / 7/8″ | 16/20/22.23 | 1.8x10mm |

| 1003.02 | 4.3” | 110 | 5/8″ / 7/8″ | 20/22.23 | 2.0x10mm |

| 1003.03 | 4.5” | 115 | 25/32″ / 7/8″ | 20 / 22.23 | 2.0x10mm |

| 1003.04 | 5” | 125 | 25/32″ / 7/8″ | 20 / 22.23 | 2.0x10mm |

| 1003.05 | 6” | 150 | 25/32″ / 7/8″ | 20 / 22.23 | 2.2x10mm |

| 1003.06 | 7” | 180 | DM / 25/32″ / 7/8″ | DM / 20 / 22.23 | 2.2x10mm |

| 1003.07 | 8” | 200 | DM / 25/32″ / 7/8″ | DM / 20 / 22.23 | 2.4x10mm |

| 1003.08 | 9” | 230 | DM / 25/32″ / 7/8″ | DM / 20 / 22.23 | 2.4x10mm |

| 1003.09 | 12” | 300 | 25/32″ / 7/8″ / 1″ | 20 / 22.23 / 25.4 | 3.2x10mm |

Continuous rim saw blade

| Art no. | Outer Diameter | Inner Diameter(H) | Segment Dimension | ||

| Inch Metric(mm) | Inch Metric(H) | ||||

| 1001.01 | 4” | 105 | 5/8” / 25/32” / 7/8” | 16/20/22.23 | 1.7x5mm |

| 1001.02 | 4.3” | 110 | 5/8” / 25/32” / 7/8” | 16/20/22.23 | 1.7x5mm |

| 1001.03 | 4.5” | 115 | 25/32″ / 7/8″ | 20 / 22.23 | 1.7x5mm |

| 1001.04 | 5” | 125 | 25/32″ / 7/8″ | 20 / 22.23 | 1.8x5mm |

| 1001.05 | 6” | 150 | 25/32″ / 7/8″ | 20 / 22.23 | 2.0x5mm |

| 1001.06 | 7” | 180 | 7/8″ / 1″ / 1-1/5″ | 22.23 / 25.4 / 30 | 2.2x5mm |

| 1001.07 | 8” | 200 | 7/8″ / 1″ / 1-1/5″ | 22.23 / 25.4 / 30 | 2.2x5mm |

| 1001.08 | 9” | 230 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 2.4x5mm |

| 1001.09 | 10” | 250 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 2.4x5mm |

| 1001.10 | 12” | 300 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 3.0x5mm |

| 1001.11 | 14” | 350 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 3.2x5mm |

Flat turbo

| Art no. | Outer Diameter | Inner Diameter(H) | Segment Dimension | ||

| Inch Metric(mm) | Inch Metric(H) | ||||

| 1002.01 | 4″ | 105 | 5/8″ / 25/32″ / 7/8″ | 16/20/22.23 | 2.0x7mm |

| 1002.02 | 4.3″ | 110 | 5/8″ / 25/32″ / 7/8″ | 16/20/22.23 | 2.0x7mm |

| 1002.03 | 4.5″ | 115 | 25/32″ / 7/8″ | 20 / 22.23 | 2.0x7mm |

| 1002.04 | 5″ | 125 | 25/32″ / 7/8″ | 20 / 22.23 | 2.0x7mm |

| 1002.05 | 6″ | 150 | 25/32″ / 7/8″ | 20 / 22.23 | 2.2x7mm |

| 1002.06 | 7″ | 180 | 7/8″ / 1″ / 1-1/5″ | 22.23 / 25.4 / 30 | 2.4x7mm |

| 1002.07 | 8″ | 200 | 7/8″ / 1″ / 1-1/5″ | 22.23 / 25.4 / 30 | 2.4x7mm |

| 1002.08 | 9″ | 230 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 2.4x7mm |

| 1002.09 | 10″ | 250 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 3.0x7mm |

| 1002.10 | 12″ | 300 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 3.2x7mm |

| 1002.11 | 14″ | 350 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 3.2x7mm |

Laser welded diamond core drill

| Art no. | Outer Diameter | Inner Diameter(H) | Segment Dimension | ||

| Inch Metric(mm) | Inch Metric(H) | ||||

| 1007.01 | 1″ | 25 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.02 | 1-1/8″ | 28 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.03 | 1-1/4″ | 32 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.04 | 1-1/2″ | 38 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.05 | 2″ | 50 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.06 | 2-1/2″ | 62 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.07 | 3″ | 75 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.08 | 3-1/2″ | 88 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.09 | 4″ | 105 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.10 | 4-1/2″ | 115 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.11 | 5″ | 125 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 3.5x10mm |

| 1007.12 | 6″ | 150 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 4.0x10mm |

| 1007.13 | 7″ | 180 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 4.0x10mm |

| 1007.14 | 8″ | 220 | 6-11/16″ / 12″ / 16″ | 170/300/400 | 4.0x10mm |

| 1007.15 | 9″ | 230 | 12″ / 16″ | 300/400 | 4.0x10mm |

| 1007.16 | 10″ | 250 | 12″ / 16″ | 300/400 | 4.0x10mm |

| 1007.17 | 12″ | 300 | 12″ / 16″ | 300/400 | 4.5x10mm |

| 1007.18 | 14″ | 350 | 12″ / 16″ | 300/400 | 4.5x10mm |

| 1007.19 | 16″ | 400 | 12″ / 16″ | 300/400 | 4.5x10mm |

| 1007.20 | 18″ | 450 | 12″ / 16″ | 300/400 | 5.0x10mm |

| 1007.21 | 20″ | 500 | 12″ / 16″ | 300/400 | 5.0x10mm |

Laser welded diamond saw blade

| Art no. | Outer Diameter | Inner Diameter(H) | Segment Dimension | ||

| Inch Metric(mm) | Inch Metric(H) | ||||

| 1006.01 | 4″ | 105 | 5/8″ / 7/8″ | 16/20/22.23 | 2.2×8 / 10mm |

| 1006.02 | 4.5″ | 115 | 25/32″ / 7/8″ | 20/22.23 | 2.2×8 / 10mm |

| 1006.03 | 5″ | 125 | 25/32″ / 7/8″ | 20 / 22.23 | 2.2×8 / 10mm |

| 1006.04 | 6″ | 150 | 25/32″ / 7/8″ | 20 / 22.23 | 2.4×8 / 10mm |

| 1006.05 | 7″ | 180 | DM / 25/32″ / 7/8″ | DM / 20 / 22.23 | 2.4×8 / 10mm |

| 1006.06 | 9″ | 230 | DM / 25/32″ / 7/8″ | DM / 20 / 22.23 | 2.6×8 / 10mm |

| 1006.07 | 12″ | 300 | 25/32″ / 1″ | 20 / 22.23 / 25.4 | 3.0×8 / 10mm |

| 1006.08 | 14″ | 350 | 1″ / 2″ | 25.4 / 50 | 3.2×8 / 10mm |

| 1006.09 | 16″ | 400 | 1″ / 2″ | 25.4 / 50 | 3.4×8 / 10mm |

| 1006.10 | 18″ | 450 | 1″ / 2″ | 25.4 / 50 | 3.6×8 / 10mm |

| 1006.11 | 20″ | 500 | 1″ / 2″ | 25.4 / 50 | 3.8×8 / 10mm |

| 1006.12 | 24″ | 600 | 1″ / 2″ | 25.4 / 50 | 4.2×8 / 10mm |

Segmented saw blade

| Art no. | Outer Diameter | Inner Diameter(H) | Segment Dimension | ||

| Inch Metric(mm) | Inch Metric(H) | ||||

| 1000.01 | 4″ | 105 | 5/8″ / 25/32″ / 7/8″ | 16/20/22.23 | 1.7x7mm |

| 1000.02 | 4.3″ | 110 | 5/8″ / 25/32″ / 7/8″ | 16/20/22.23 | 1.7x7mm |

| 1000.03 | 4.5″ | 115 | 25/32″ / 7/8″ | 20 / 22.23 | 1.7x7mm |

| 1000.04 | 5″ | 125 | 25/32″ / 7/8″ | 20 / 22.23 | 1.8x7mm |

| 1000.05 | 6″ | 150 | 25/32″ / 7/8″ | 20 / 22.23 | 2.0x7mm |

| 1000.06 | 7″ | 180 | 7/8″ / 1″ / 1-1/5″ | 22.23 / 25.4 / 30 | 2.2x7mm |

| 1000.07 | 8″ | 200 | 7/8″ / 1″ / 1-1/5″ | 22.23 / 25.4 / 30 | 2.2x7mm |

| 1000.08 | 9″ | 230 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 2.4x7mm |

| 1000.09 | 10″ | 250 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 2.4x7mm |

| 1000.10 | 12″ | 300 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 3.0x7mm |

| 1000.11 | 14″ | 350 | 7/8″ / 1″ / 1-1/5″ / 2″ | 22.23 / 25.4 / 30 / 50 | 3.2x7mm |

Segmented single / Double row cupwheel

| Art no. | Outer Diameter | Segment dimension(TxH) | Segment Dimension | ||

| Inch Metric(mm) | |||||

| 1008.01 | 4″ | 100 | 25/32″ / 7/8″ | 20/22.23 | – |

| 1008.02 | 4.5″ | 115 | 25/32″ / 7/8″ | 20/22.23 | – |

| 1008.03 | 5″ | 125 | 7/8″ | 22.23 | – |

| 1008.04 | 6″ | 150 | 7/8″ | 22.23 | – |

| 1008.05 | 7″ | 180 | 7/8″ | 22.23 | – |

| 1008.06 | 4″ | 100 | 25/32″ / 7/8″ | 20/22.23 | 32x5x8mm / 20x5x8mm |

| 1008.07 | 4.5″ | 115 | 25/32″ / 7/8″ | 20/22.23 | 31x5x8mm / 22x5x8mm |

| 1008.08 | 5″ | 125 | 7/8″ | 22.23 | 31x5x8mm / 24x5x8mm |

| 1008.09 | 6″ | 150 | 7/8″ | 22.23 | 32x5x8mm / 24x5x8mm |

| 1008.10 | 7″ | 180 | 7/8″ | 22.23 | 35x5x8mm / 28x5x8mm |

TCT saw blade

| Art no. | Outer Diameter | Inner Diameter(H) | Segment Number | Segment Dimension | |

| Inch Metric(mm) | mm | ||||

| 1009.01 | 4.3″ | 110 | 16 / 20 / 22.23 | 20T, 24T, 30T, 40T | 1.2 / 1.8 |

| 1009.02 | 5″ | 125 | 20 / 22.23 | 20T, 24T, 30T, 40T | 1.2 / 1.8 |

| 1009.03 | 6″ | 150 | 20 / 22.23 | 20T, 24T, 30T, 40T | 1.4 / 2.0 |

| 1009.04 | 6.5″ | 165 | 20 / 22.23 | 24T, 30T, 40T, 60T | 1.4 / 2.0 |

| 1009.05 | 7-1/4″ | 185 | DM / 20 / 22.23 | 24T, 30T, 40T, 60T | 1.4 / 2.2 |

| 1009.06 | 8.3″ | 210 | DM / 20 / 22.23 | 24T, 30T, 40T, 60T | 1.4 / 2.2 |

| 1009.07 | 9″ | 230 | DM / 20 / 22.23 | 30T, 40T, 60T, 80T | 1.8 / 2.6 |

| 1009.08 | 10″ | 255 | 20 / 22.23 / 25.4 | 40T, 60T, 80T, 100T | 1.8 / 2.9 |

| 1009.09 | 12″ | 305 | 20 / 22.23 / 25.4 | 40T, 60T, 80T, 120T | 2.0 / 3.1 |

| 1009.10 | 14″ | 355 | 20 / 22.23 / 25.4 | 40T, 60T, 80T, 120T | 2.0 / 3.4 |

| 1009.11 | 16″ | 400 | 22.23 / 25.4 / 50 | 40T, 60T, 80T, 120T | 2.4 / 3.4 |

| 1009.12 | 18″ | 450 | 25.4 / 50 | 40T, 60T, 80T, 120T | 2.5 / 3.6 |

| 1009.13 | 20″ | 500 | 25.4 / 50 | 60T, 80T, 100T, 120T | 3.0 / 3.6 |

| 1009.14 | 24″ | 600 | 25.4 / 50 | 60T, 80T, 100T, 120T | 3.0 / 3.6 |

| 1009.15 | 30″ | 700 | 25.4 / 50 | 60T, 80T, 100T, 120T | 4.0 / 5.0 |

Turbo cup wheel

| Art no. | Outer Diameter | Inner Diameter(H) | Segment Dimension | ||

| Inch Metric(mm) | Inch Metric(H) | ||||

| 1008.11 | 4″ | 100 | 5/8″ | 16/20/22.23 | 20×5.5mm |

| 1008.12 | 4.5″ | 115 | 25/32″ / 7/8″ | 20/22.23 | 20×5.5mm |

| 1008.13 | 5″ | 125 | 25/32″ / 7/8″ | 20 / 22.23 | 20×5.5mm |

| 1008.14 | 6″ | 150 | 25/32″ / 7/8″ | 20 / 22.23 | 20×5.5mm |

| 1008.15 | 7″ | 180 | 25/32″ / 7/8″ | 20 / 22.23 | 20×5.5mm |

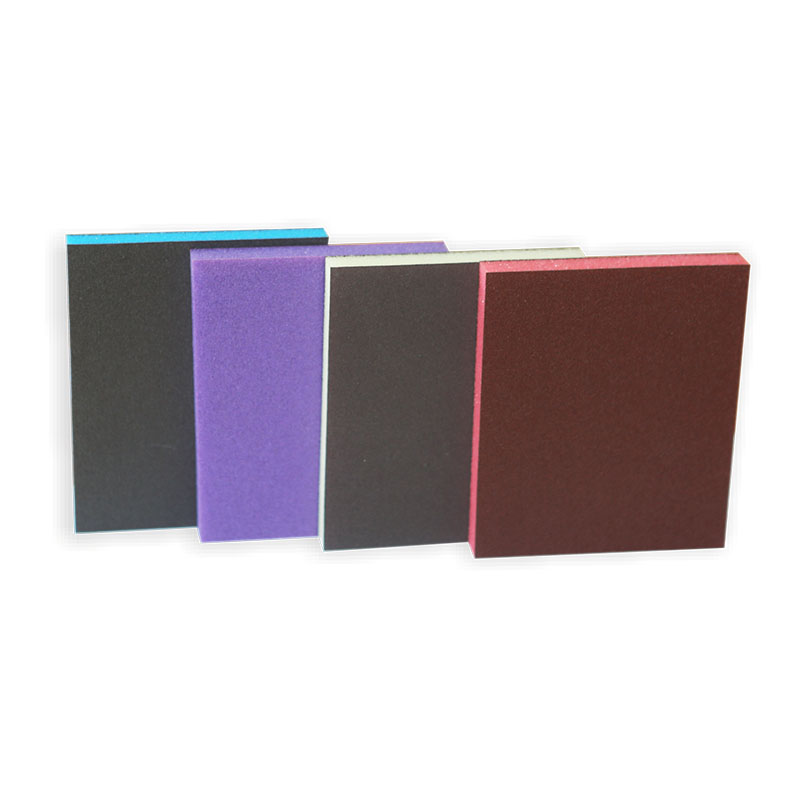

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for Newly Arrival Diamond Sandpaper - Diamond series products – Orientcraft , The product will supply to all over the world, such as: Gabon, Algeria, Marseille, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.