China Manufacturer for Endless Belts - Endless belts – Orientcraft

China Manufacturer for Endless Belts - Endless belts – Orientcraft Detail:

Art no.115.10

Endless belts

MATERIAL: Aluminium oxide & Zirconia oxide abrasive.

APPLICATION: High speed sanding and finishing of flat surfaces on wood, plastic, fiberglass and stainless steel.

FEATURES: Highly resistant product designed for portable or nonportable belt sanders.

JOINT: Lap joint, Butt joint and S joint.

SIZE: Any other sizes as customer’s requirement.

PREMIUM-QUALITY SANDING BELTS

ORIENTCRAFT Abrasives is a family-owned abrasive manufacturer that has been producing premium-quality abrasives for over 15 years. Our sanding belts are designed to be affordable, effective, and long-lasting. Sanding belts are available in a variety of sizes from ¼” x 18” all the way up to 60” x 360” and beyond (popular sizes include 2 x 72, 2 x 42, 1 x 30, 2 x 48, 3 x 18, 4 x 36, and 4 x 24). ORIENTCRAFT offers belts in several different abrasive grains and backings. Regardless of your application, we have the belts you need to finish your piece to perfection.

WHAT TYPE OF ABRASIVE GRAIN DO I NEED FOR MY SANDING BELTS?

ORIENTCRAFT Abrasives offers grinding belts in four different types of abrasive grains: ceramic, zirconia, silicon carbide, open coat aluminum oxide, and closed coat aluminum oxide. The best abrasive grain for your needs will depend on your application.

Open coat aluminum oxide works great for softer woods. Silicon carbide is commonly used to finish heat sensitive applications. Ceramic, zirconia, and closed coat aluminum oxide are all designed to work well with hardwoods and metals. Closed coat aluminum oxide has the shortest lifespan and ceramic has the longest. Zirconia sits in-between ceramic and closed coat aluminum oxide in terms of price and longevity. If you’re working with hardwood or metal, we would recommend ceramic as the best bang for your buck.

WHICH TYPE OF SANDING BELT BACKING IS BEST FOR MY APPLICATION?

ORIENTCRAFT Abrasives offers grinding belts with paper or cloth/polyester backings. Paper backings are the lightest and most popular backing options. What paper lacks in strength it makes up for in affordability. Cloth is more expensive than paper, but it’s also more durable. Cloth is worth the investment if you plan on grinding or finishing with applications that involve a lot of bending and flexing in the belt. Cloth belts can also be washed to help extend their lifespan. You can read more about the differences between cloth and paper backings in our post on abrasive backings.

HOW DO I KNOW WHAT SIZE SANDING BELT I NEED?

Don’t know what size sanding belt you need? There are easy ways to determine the right size for your belt sander.

If you have an old belt laying around, you can cut the belt at the seam and lay it out flat to measure the length and width. If you don’t have an old belt, you can wrap a string around your belt sander the same way you’d wrap your belt around the sander. You can cut the string where it wraps around to touch the end of the string and measure the length to determine the right belt length. You can also measure the width of the belt wheel to find the correct width for your belts.

COMMON APPLICATIONS FOR SANDING BELTS

Sanding belts and belt sanders can be used for many different applications. Sanding belts are commonly used in the production of knives (for stock removal, sharpening, profiling, polishing, and more), wooden toys, furniture, axes, arrows, musical instruments, art pieces, and more. Not sure if belt sanding is the right fit for your application? Our abrasive technicians can help point you towards the abrasives that will be best for your needs.

GRINDING BELT QUESTIONS? CONTACT OUR ABRASIVE SPECIALISTS

If you have questions about sanding belts, abrasives, or ORIENTCRAFT Abrasives, our abrasive specialists would be more than happy to help! We are here to serve you.

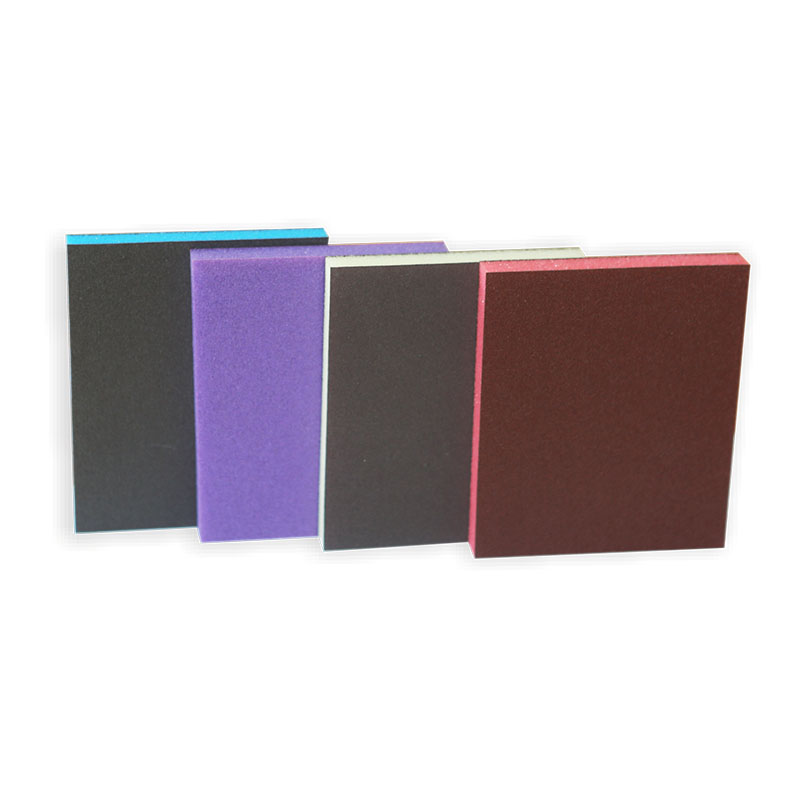

Product detail pictures:

Related Product Guide:

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for China Manufacturer for Endless Belts - Endless belts – Orientcraft , The product will supply to all over the world, such as: Irish, Bangladesh, Austria, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.