Best quality Resin Bond Grinding Wheel - Flap discs – Orientcraft

Best quality Resin Bond Grinding Wheel - Flap discs – Orientcraft Detail:

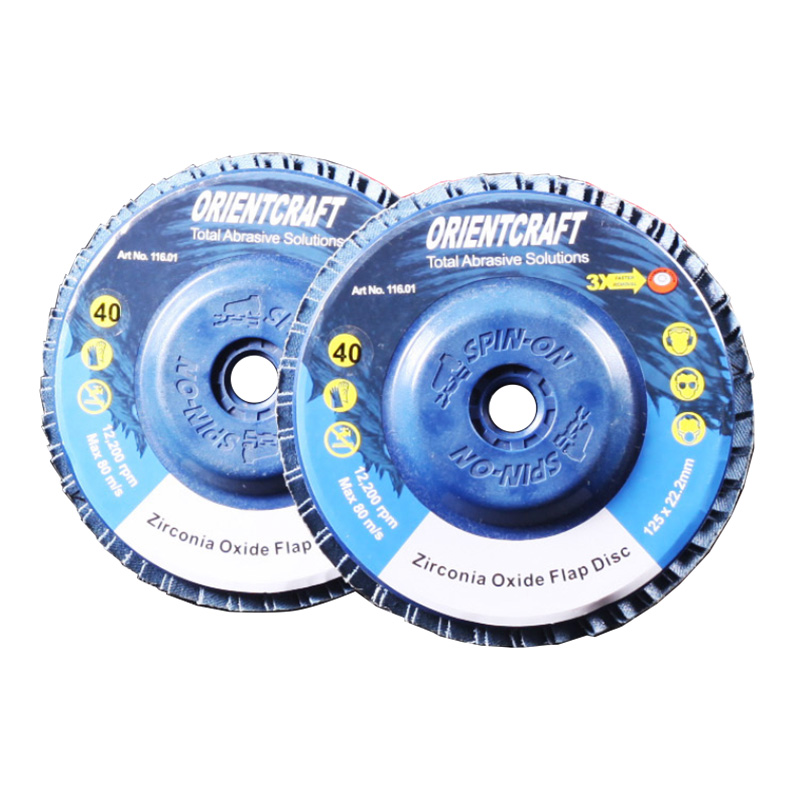

Art no.116.00

HOT

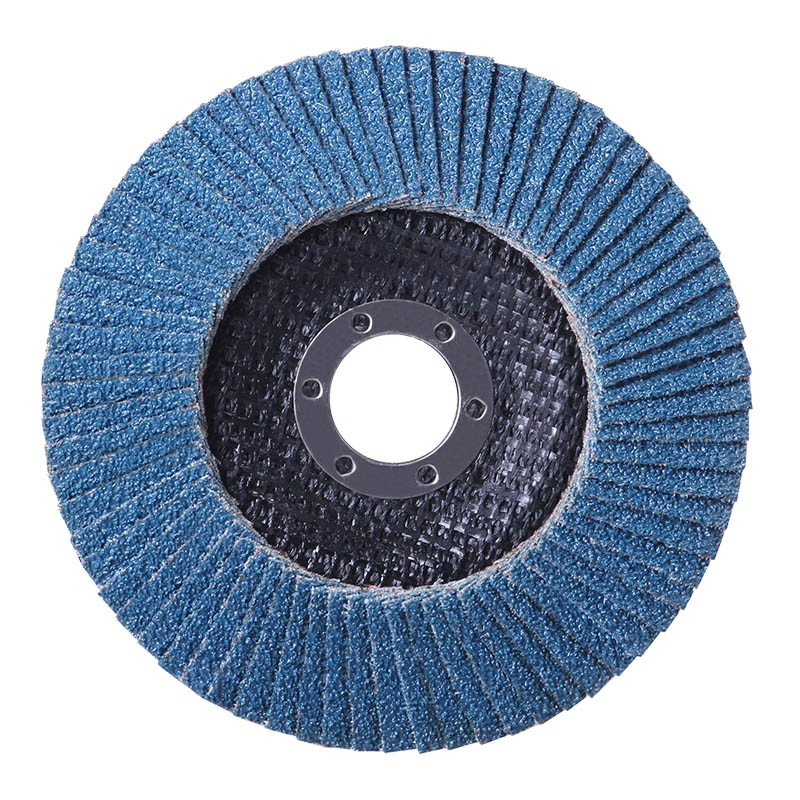

Flap discs

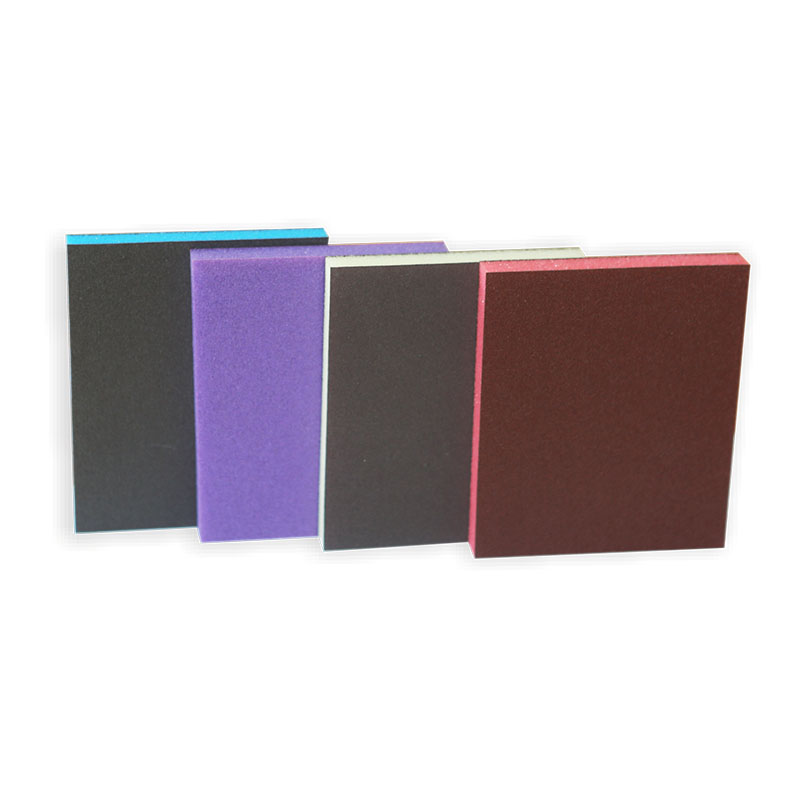

MATERIAL: Aluminium oxide, Zirconium oxide, Ceramic aluminium oxide or Black silicon carbide abrasives. Fiber or plastic body. Flat or tapered profile.

APPLICATION: Removing materials, edges, chamferings, burrs rust, trimming of weld joints, surface cleaning and finishing.

FEATURES: Powerful and quick sharpening, preventing workpieces from being burnt. High grinding efficiency, good safety in use and long service life.

GRIT RANGE: 24-120

DISCS: Dia.50mm, Dia.75mm, Dia.100mm, Dia.115mm, Dia.125mm, Dia.150mm, Dia. 180mm.

HIGH DENSITY ABRASIVE FLAP DISCS

These flap discs are perfect for removing large amounts of material and for shaping or smoothing wood & metal. They are manufactured for rapid stock removal while delivering exceptionally fast and cool cuts. They are offered in Ceramic with grits ranging from 36 to 120 grit and have an angled face of the disc.

WHAT IS A HIGH DENSITY (HD) FLAP DISC?

High density ceramic flap discs are 2X the size of a normal flap disc and can last 2-3X the life of a normal ceramic flap disc due to its powerful performance & extra material that is jam packed into this flap disc. This flap disc will last 6 times longer than a zirconia flap disc and up to 10 times longer than an aluminum oxide flap disc.

When you receive this you will honestly be blown away by how THICC it is …..That’s right! Two extra C’s!

WHAT IS THE DIFFERENCE BETWEEN TYPE 27 AND TYPE 29 FLAP DISCS?

Type 27 flap discs have a flat surface to them. Type 29 flap discs an angled or pitched surface. In other words, Type 27 is flat and type 29 is not flat, its angled. We carry type 29 flap discs because that is the most common disc type and we feel is more versatile when fabricating.

WHY IS TYPE 29 FLAP DISCS BETTER THAN TYPE 27 FLAP DISCS?

We strongly feel that type 29 flap discs are much better and more versatile when wood or metal fabricating and the industry thinks so also!

Type 29 has a angled shape which allows for better contouring.

It is also better for shaping surfaces because of its 15 degree angle.

More accessibility when grinding edges or welds.

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Best quality Resin Bond Grinding Wheel - Flap discs – Orientcraft , The product will supply to all over the world, such as: Ecuador, El Salvador, Dominica, Faced with the vitality of the global wave of economic integration, we are confident with our high-quality products and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!